TECNA TE470 Resistance Welder Controller

Price: Contact

The TE470 can store up to 63 welding programs, with 2 programs directly selectable via an external selector usually mounted on the handle, even when two handles are in use. Each program consists of 19 adjustable parameters describing the welding cycle. Beyond the basic 4-step cycle, it supports pre-weld current, post-weld current, slope, and pulse settings. The TE470 can operate in constant current mode, displaying and monitoring welding current according to preset limits.

Product details

Product category

Product description

TECNA TE470 Resistance Welder Controller

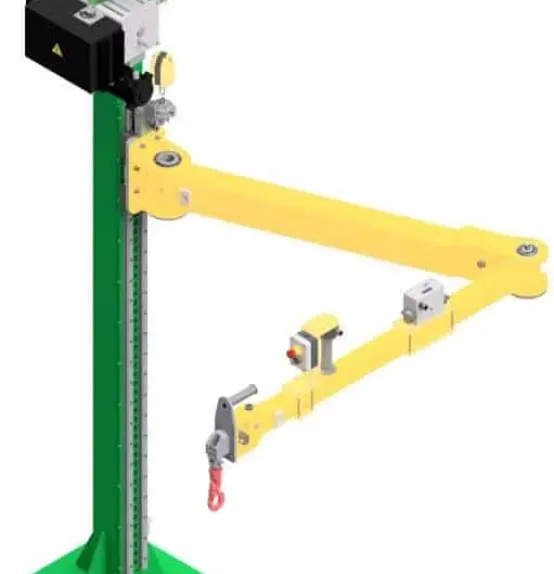

The TECNA TE470 is a microprocessor-based controller designed for suspended resistance welding guns. It manages the components of the welding machine, particularly the thyristors that regulate welding current. The controller includes specialized functions for suspended guns, such as double stroke control and monitoring of safety devices that may be installed on the gun handle. The handle itself is not a standard component; different types of handles can be installed to configure the machine for various performance requirements.

The TE470 can store up to 63 welding programs, with 2 programs directly selectable via an external selector usually mounted on the handle, even when two handles are in use. Each program consists of 19 adjustable parameters describing the welding cycle. Beyond the basic 4-step cycle, it supports pre-weld current, post-weld current, slope, and pulse settings. The TE470 can operate in constant current mode, displaying and monitoring welding current according to preset limits.

Features of TECNA TE470

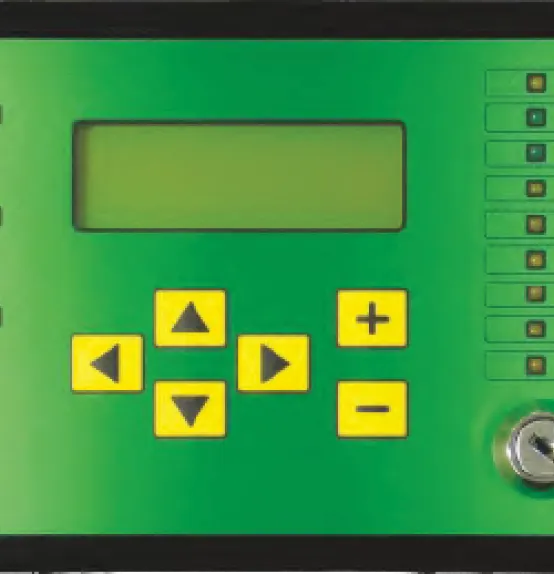

Simple programming via 5 push buttons and numeric LCD.

Synchronized control using controlled diodes with phase shift adjustment for welding current regulation.

Stores 63 welding programs; 2 programs directly selectable from the gun handle.

Supports connection of 2 gun handles.

19 or more programmable parameters per program.

Slope and Pulse functions; Pre-weld and Post-weld functions.

Half-cycle welding time adjustment.

Displays welding current in kA and conduction angle.

Operating modes: Conventional and Constant Current.

Limits for welding current or conduction angle.

Automatic double stroke function (requires machine configured for this function).

Three stroke modes along machine travel: Short (SHORT), Long (LONG), and Automatic (AUTO).

Stepper function to compensate for electrode wear via adjustable curve.

Welds counter.

Single and automatic welding cycles; Weld/No-Weld function.

First phase shift delay for optimal power consumption balance.

Controls 2 solenoid valves (24 VDC, max 7.2 W) with short-circuit-protected outputs: electrode clamp and double stroke.

Auto-adjusts to 50/60 Hz mains frequency.

RS485 data communication.

Password-protected programming.

Selectable languages: Italian, English, Spanish, German, French, Hungarian, Portuguese, Swedish.

Specifications are subject to change without notice.